Summer is winding down and I am attempting to wind back up for my first semester as an official master's candidate. Part of me is still mourning the end of summer and freedom, but the other half of me is excited because there is nothing quite like a university campus in fall...the smell of laundry in the back of a brick dormitory, the line of chattering students in the bookstore, the timeworn pavement beneath your feet and leaves that are just starting to crackle, stacks of beautiful books, sunny-but-not-sweaty-with-a-hint-of-autmun-chill days in which to cherish the last bit of your summer wardrobe, and sweaters and layered looks and boots just around the corner as fall encroaches completely.

ok, these did not look all neon-y weird when I was editing them...

methinks this laminated surface must pick up some strange lighting reflections in photos.

methinks this laminated surface must pick up some strange lighting reflections in photos.

Given that, there couldn't be a better time to share this project with you! Just before my sewing machine broke over the summer, I was able to finish this lunchbag made with laminated cotton (traditionally oilcloth). Because I don't have the luxury of a fridge at work and am on the go all day, a layer of cotton batting acts as a great insulator to keep things cold or hot longer. I love it because I go from 9am to 9pm every Monday and Wednesday packing in both work and classes, so a fresh and cheap lunch is a godsend for both my waistline and my wallet. Plus, making it double-sided adds versatility and makes it easy to clean so no arguments there (I stick it right under the faucet, and BAM! I am done with my lunch dishes!).

Detail of the grommet + ribbon closure

To finish it off, I decided to go with a grommet and some grosgrain ribbon since it's more permanent than a clip and doesn't present the same difficulties that velcro would in sewing it down to a double-sided piece. Either which way you turn it, the grommet is there and the ribbon can be stashed inside or even top-stitched to the bag itself so as not to loose it.

Below, you can find how to make these changes, using the following tutorial as a starting off point:

Oilcloth lunch bag by Tumbling Blocks

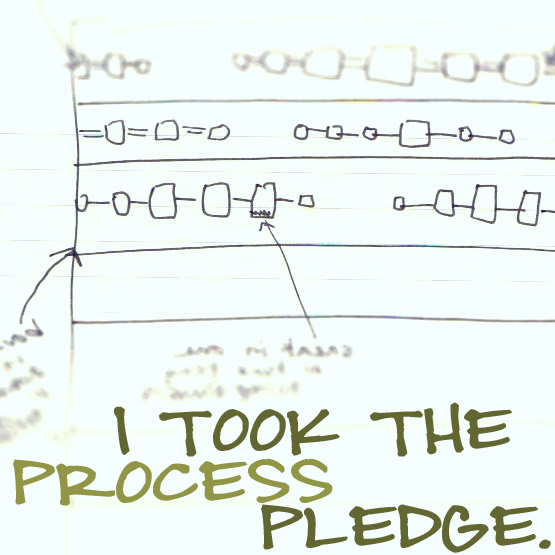

Tips for working with laminated cotton and oilcloth, from left to right: A, B, C

First off, there are three important tips on working with oilcloth or laminated cotton—

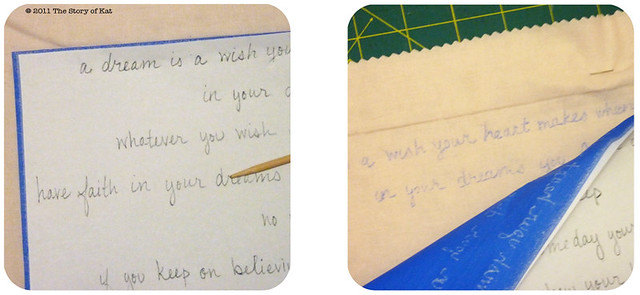

A: Don't use pins! Like working with plastic or leather, they will leave permanent holes in your fabric. Instead, try hair pins or paper clips to hold layers together while you sew.

B: To sew with these slippery and thicker fabrics, you will want to use a walking foot for your machine. If you don't have one, you can use a bit of painter's tape on the bottom of your regular foot so that it can run smoothly along (masking tape works too, but the painter's tape is sure not to leave residue). Just cut a hole so that your needle can go through uninhibited.

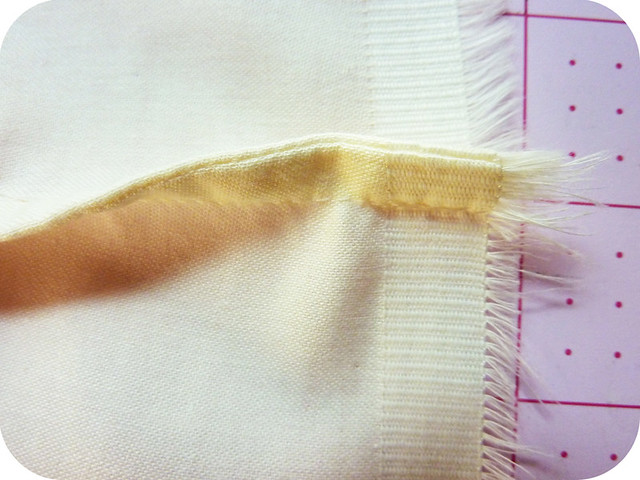

C: Instead of cutting triangles, cut straight slits at the corners of seams so as to reduce bulk and increase flexibility.

This is a great resource for even more tips for working with oilcloth, including guidance on choosing an appropriate needle size and stitch length:

Oilcloth International Blog

Clockwise, from top left: 1, 2, 3, 4.

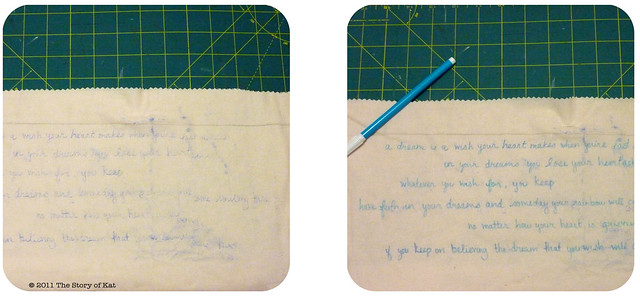

Following the technique and dimensions of the linked tutorial, you will make three bags—two from your chosen laminates, and one from cotton batting at a 1/4 inch smaller on all sides than the other two. Once you've done that, follow these simple steps to finish your bag, referring to the photos above:

1. With one of the oilcloth bags turned right-side out, slip your batting layer into it, making sure the corners are flush with eachother as much as possible.

2. Next, slip your second oilcloth layer (right-side in) into the batting so that you have the three bags sandwiched into one with the batting in the middle and the oilcloth facing out on both sides. If the ends of your bag do not quite match up, you can trim them to reduce bulk, however, you will need some extra to tuck in so that you can create a clean edge so read on first, and don't worry about that too much.

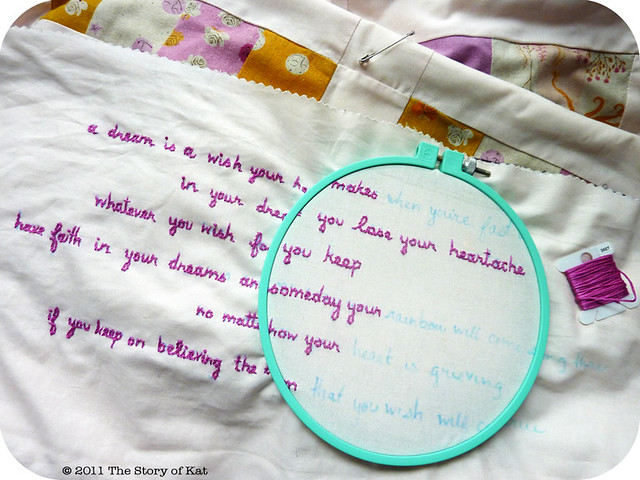

3. As you can see in the photo, you will want to fold the edges of both laminates towards the middle so that they meet as if you are getting ready to close it with a ladder stitch.

4. Pin as you go with the hairpins and then topstitch all the way around a couple times to close it up.

Following the package directions for your grommets, attach one at a time to each side of the bag app. 4–5 inches down from the top edge and directly lined up with each other. Make sure you place them down far enough to fold the top edge over however many times you prefer. Secure fold with a 6–8 inch piece of ribbon (a grosgrain ribbon will fray the least and you can hand stitch it down to one side of the bag so as not to lose it)

TADA, you are ready to eat some lunch!

Most other tutorials you will find call for topstitching along all the seams of the bag, but if you are going to go for the insulation and double-sided approach, you will find that is not possible. With all these layers and the food you actually put into it, you are pretty much good-to-go for structure anyhow, but you could do it by hand if you really want those straight lines for the finished product.